In recent years, Virtual Reality industrial trainings has emerged as a transformative technology with the potential to revolutionize various sectors, including the manufacturing and engineering industry.

Traditional training methods in these industries often involve high costs, safety risks, and limited accessibility.

However, VR training offers a groundbreaking solution by providing immersive and interactive experiences that enable employees to learn in a virtual environment.

Virtual reality is all about democratizing storytelling. It gives people more control over the experience. Instead of trying to force a story upon you, we try and give you this huge playground through which you will create stories that you will then share through this medium.

CURTIS HICKMAN Tweet

Table of Contents

This blog will explore the benefits and applications of VR training in the manufacturing and engineering industry, highlighting its potential to enhance efficiency, safety, and productivity.

Enhancing Learning through Immersion:

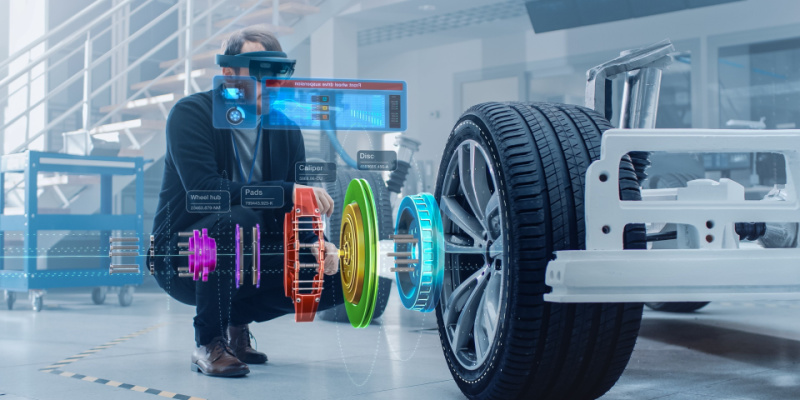

VR training enables trainees to step into a virtual environment that simulates real-life scenarios, providing a high level of immersion.

This immersive experience allows employees to learn by doing, enhancing their understanding of complex manufacturing processes and engineering concepts.

For example, trainees can practice assembly line operations, equipment maintenance, or even experience hazardous situations in a safe and controlled virtual environment.

By engaging multiple senses and promoting active participation, VR training boosts knowledge retention and skill development.

Improving Safety:

Safety is paramount in the manufacturing and engineering industry. VR training offers a safe environment to learn and practice safety protocols without exposing trainees to real-life hazards.

By simulating dangerous scenarios, such as handling hazardous materials or operating heavy machinery, VR training ensures that employees are well-prepared to deal with potential risks.

Furthermore, trainees can learn emergency response procedures and practice them in realistic simulations, empowering them to act swiftly and effectively in critical situations.

Cost and Time Efficiency:

Traditional training methods often involve significant costs related to equipment, materials, and facility setup.

Additionally, the time required to coordinate training sessions and gather resources can be extensive.

VR training eliminates many of these expenses by providing a virtual platform that requires minimal physical resources.

Once the virtual environment is created, it can be replicated for multiple training sessions, reducing costs associated with repetitive training.

Moreover, VR training enables employees to learn at their own pace, allowing for flexible scheduling and reducing the time required for training.

Accessible and Scalable Training:

One of the challenges in the manufacturing and engineering industry is the accessibility of training programs.

VR training overcomes geographical limitations by providing remote access to training modules. This means that employees across different locations can receive consistent and standardized training without the need for travel.

Furthermore, VR training can be easily scaled to accommodate the growing workforce, as virtual simulations can be replicated and shared across various devices, making it accessible to a larger number of trainees simultaneously.

Real-Time Feedback and Performance Assessment:

VR training offers real-time feedback, enabling trainees to learn from their mistakes immediately.

Virtual environments can track and analyze trainees’ actions, providing comprehensive performance assessments.

This feedback allows employees to identify areas of improvement and refine their skills.

Furthermore, VR training can generate performance metrics and progress reports, enabling employers to assess the effectiveness of the training program and identify areas that require additional focus or improvement.

Simulating Complex Scenarios and Specialized Skills:

Manufacturing and engineering industries often involve intricate processes and specialized skills.

VR training can effectively simulate complex scenarios and provide trainees with hands-on experience in dealing with challenging situations. For instance, VR can be used to simulate intricate assembly processes, fine-tuning welding techniques, or training for operating specialized machinery.

By practicing in a virtual environment, trainees can refine their skills and gain confidence in handling complex tasks before applying them in the real world.

Collaboration and Remote Training:

In addition to individual training, VR platforms enable collaborative learning experiences. Trainees can participate in virtual group exercises, allowing them to work together and practice teamwork in a simulated environment.

Moreover, VR training can facilitate remote collaboration, bringing together experts and trainees from different locations in a shared virtual space.

This capability is particularly valuable in industries where specialists or trainers may not be physically present at every location, ensuring consistent knowledge transfer and fostering a culture of collaboration.

At the moment, VR is really about lessons learned. It's in an exciting (and frightening) experimentation stage, something that might not be perfect during the first go-around but should still be invested in. This is the way we will start breaking new ground and challenging the norms.

RESH SIDHU Tweet

Conclusion

Virtual Reality (VR) training has immense potential to revolutionize the manufacturing and engineering industry.

Its immersive nature, cost efficiency, scalability, and ability to simulate complex scenarios make it an ideal tool for training and skill development. By leveraging VR, organizations can enhance learning outcomes, improve safety, and increase productivity.

As technology continues to advance, we can expect VR training to become an integral part of training programs, providing employees with the skills and knowledge they need to thrive in the manufacturing and engineering sectors.