Introduction

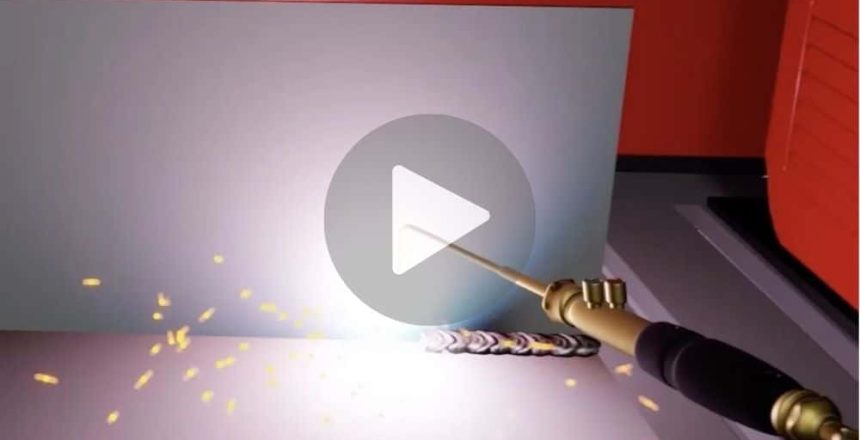

In the rapidly evolving landscape of industrial training, Twinreality, a leader in virtual reality innovations, introduces its groundbreaking welding VR simulation. Explores how this advanced simulation tool is set to transform the traditional methodologies of welding training.

Market Overview

The VR welding simulation market is characterized by diverse applications across various industries. These tools have been pivotal in sectors like vocational training, heavy industries, and skill development centers, offering a blend of safety, efficiency, and immersive learning experiences. As a key player in this space, new VR simulation is poised to bring a fresh perspective to this technological arena.

Key Features of VR Welding Simulations

Contemporary VR welding simulations offer features such as realistic welding scenarios, educational tools, and immersive technology. These aspects have set high standards in the market, establishing a benchmark for quality and innovation. This VR simulation aligns with these industry standards while introducing its unique enhancements.

Innovative Aspects of Twinreality's Product

Welding VR simulation stands out with its unique attributes:

- Real-World Application Integration: The simulation integrates real-world applications, preparing trainees for actual on-field scenarios. This is particularly beneficial in industries like construction and automotive, where precision and skill are paramount. More on VR’s impact in these sectors can be found on our VR in construction industry and VR for the automotive industry

- Diverse Industrial Applications:Designed for versatility, the simulation caters to sectors including manufacturing, engineering, aviation, and defense. Insightful articles on VR’s role in these industries are available on our VR in aviationand virtual reality for defense pages

- Customization and Scalability: Recognizing the uniqueness of industries and learners, the simulation offers extensive customization and scalability, ensuring it remains relevant and effective as technology and industry needs evolve.

Benefits and Applications

The benefits of Twinreality’s VR simulation extend beyond training, offering skill assessment, continuous learning, and standardization of training across locations. The immersive learning environment enhances understanding and retention, crucial in technical education. The wide-reaching potential of VR in industrial training is further explored in our articles on VR industrial training and top 7 VR industrial training applications.

Challenges and Future Directions in VR Welding Simulation

The journey of integrating VR into welding training is not without its challenges. One significant hurdle is the initial investment in VR technology, which can be substantial. However, Twinreality addresses this by offering scalable solutions that cater to different budgetary requirements. For more insights into the affordability and ROI of VR training, our article on VR for business provides valuable information.

Another challenge lies in the skepticism regarding the efficacy of VR training compared to traditional methods. To dispel these doubts, Twinreality’s simulation incorporates advanced analytics and reporting features, offering tangible evidence of its effectiveness. This aspect is crucial for industries where precision and skill are non-negotiable, such as in VR safety trainings in refineries and VR in electrical safety training.

As for future directions, is committed to continuous innovation. We are exploring the integration of AI and machine learning to provide even more personalized training experiences. Our ongoing research in this area aligns with the broader trends in VR, as seen in our exploration of virtual reality for product design.

Educational Impact and Societal Benefits

The educational impact of welding VR simulation extends beyond traditional learning environments. It has the potential to revolutionize vocational training, making it more accessible and engaging. This is particularly relevant in sectors like VR in the mining industry and VR in the aviation industry, where hands-on experience is invaluable.

Moreover, our VR simulation plays a pivotal role in societal benefits. By providing a safer and more controlled training environment, it reduces the risk of accidents and injuries, a significant concern in industries like mining and construction. The use of VR in these sectors is not just a technological upgrade but a commitment to safety and efficiency.

Integration with Broader Training Programs

Twinreality’s VR welding simulation is designed to seamlessly integrate with broader training programs. This integration is particularly beneficial in sectors like VR in the construction industry and VR for the automotive industry, where training needs are diverse and dynamic.

Furthermore, our VR simulation aligns with various educational frameworks, supporting both secondary and tertiary education programs. It can be a valuable tool in VR in education, offering an interactive and immersive learning experience

Conclusion

Twinreality’s welding VR simulation represents a significant leap in industrial training. By harnessing the power of virtual reality, it offers a versatile, efficient, and engaging training tool that transcends traditional methods. Its applications extend across numerous industries, offering benefits that include enhanced safety, improved skill acquisition, and greater accessibility.

As we continue to innovate and refine our VR simulation, we invite you to explore the possibilities it opens up for your industry. Whether you are in manufacturing, engineering, or any other sector where welding skills are essential, Twinreality is poised to be your partner in training excellence. For more information on how VR is revolutionizing various industries, visit our VR operator training simulators page.

Join us as we continue to explore and expand the frontiers of VR in welding training, setting new benchmarks in industrial education and skill development.

- It can cost between 5000$ to 8000$ depending upon different possible features

- It provides a realistic, risk-free training environment with immediate feedback, improving skill acquisition and safety.

- Yes, it’s designed for seamless integration with various training programs in different industries.

- Yes, it caters to beginners to advanced learners with customizable scenarios and difficulty levels.

- VR headsets and controllers are required, with specific requirements depending on the simulation version.

- Yes, it provides detailed analytics and reports on technique precision, speed, and overall skill development.